Best-Selling 3d Printed Injection Mold - Most common way to produce large volume production – Colead

Best-Selling 3d Printed Injection Mold - Most common way to produce large volume production – Colead Detail:

Description

Currently plastic injection molding is still the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use.

Advantages

There are many advantages of injection molding:

● Wide plastic resins to choose from for any application.

● Standard lead time 2-4 weeks for T1 samples.

● Most cost-effective way to make large volumes of parts fast.

● A single tool can last for up to millions of cycles.

● Excellent surface quality and dimensional characteristics can be achieved.

● Variety of polishing and texturing capabilities.

● Different plastics can be overmolded for even more design options.

● Injection molding is stable and reliable for predictable result.

● Free Design for Manufacturing Analysis (DFM) with each quote.

Application

Almost for every kind of commercial and industrial use.

In Colead we are producing high-quality plastic injection molded parts and mold tooling. We supply plastic injection manufacturing for many world first -class companies. We are offering all machining and finishing services to make tooling from a variety of materials, and produce 100 to 200k+ finished parts in all major plastics. Our advanced material verification, inspection and testing will ensure your parts meet and exceed your expectations.

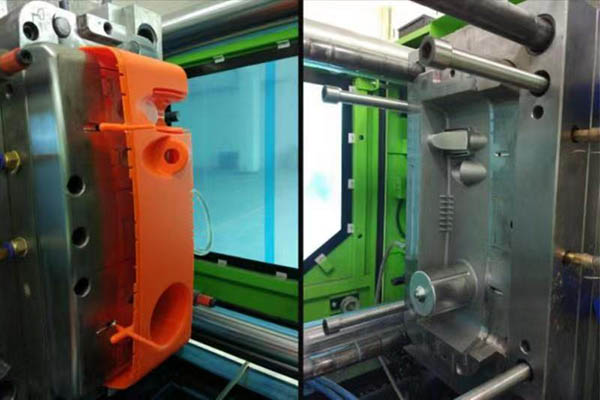

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Best-Selling 3d Printed Injection Mold - Most common way to produce large volume production – Colead , The product will supply to all over the world, such as: Mexico, Provence, Buenos Aires, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.