Featured

-

factory low price Titanium Sheet Metal - Sheet metal operations from prototype to high volume production – Colead

Description Sheet metal can be cut, bent, and stretched into nearly any shape. The size of sheet metal parts can range from a small washer or bracket to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture. Quotes are generated with STEP, IGES or most native CAD files. Material thickness can range from 0.001″ – 0.250″. Advantages ... -

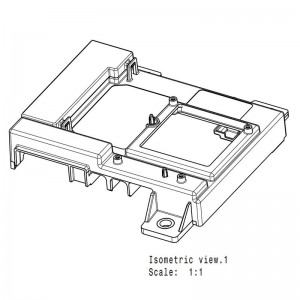

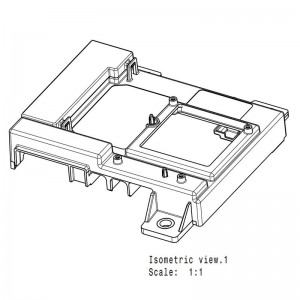

OEM Manufacturer Application Of Rapid Tooling - Fast delivery in 3 weeks rapid tooling case – Colead

Description Request– Complete a rapid tooling and finish 60 parts for testing in 3 weeks. It is a part is for the automotive electronic system. Problem – Although this was an internal part perfection was called for to reduce noise (created by air flow) as much as possible. To achieve the desired end result, we need to ensure there is no flash and no interior surface imperfections. Solution – To achieve perfection. During injection molding, perfect tool finishing and extra attention is need to... -

High definition Bendable Metal Sheets - Small batch Al6061 sheet metal case – Colead

Description Sheet metal can be cut, bent, and stretched into nearly any shape. The size of sheet metal parts can range from a small washer or bracket to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture. Quotes are generated with STEP, IGES or most native CAD files. Material thickness can range from 0.001″ – 0.250″. Project S... -

18 Years Factory Injection Parts - Build prototyping parts without limitation of geometry by 3D Printing – Colead

Description ● Stereolithography (SLA) Highest accuracy and smoothest surface finish of all 3D printed parts. Print highly detailed parts ranging from just a few mm in size, all the way up to 5 ft (1.5 m), with exceptional resolution and accuracy and virtually no part shrink or warping. ● Selective Laser Sintering (SLS) Capable of producing highly durable and complex geometries for real-world testing while other additive manufacturing methods may become brittle over time. Ideal for snap fits a... -

Factory directly supply Mild Steel Sheet Metal - Small batch Al6061 sheet metal case – Colead

Description Sheet metal can be cut, bent, and stretched into nearly any shape. The size of sheet metal parts can range from a small washer or bracket to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture. Quotes are generated with STEP, IGES or most native CAD files. Material thickness can range from 0.001″ – 0.250″. Project S... -

100% Original Checkered Sheet Metal - Sheet metal operations from prototype to high volume production – Colead

Description Sheet metal can be cut, bent, and stretched into nearly any shape. The size of sheet metal parts can range from a small washer or bracket to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture. Quotes are generated with STEP, IGES or most native CAD files. Material thickness can range from 0.001″ – 0.250″. Advantages ... -

OEM/ODM Supplier Sls Printing Materials - Build prototyping parts without limitation of geometry by 3D Printing – Colead

Description ● Stereolithography (SLA) Highest accuracy and smoothest surface finish of all 3D printed parts. Print highly detailed parts ranging from just a few mm in size, all the way up to 5 ft (1.5 m), with exceptional resolution and accuracy and virtually no part shrink or warping. ● Selective Laser Sintering (SLS) Capable of producing highly durable and complex geometries for real-world testing while other additive manufacturing methods may become brittle over time. Ideal for snap fits a... -

New Delivery for Silicone Prototyping - Build prototyping parts without limitation of geometry by 3D Printing – Colead

Description ● Stereolithography (SLA) Highest accuracy and smoothest surface finish of all 3D printed parts. Print highly detailed parts ranging from just a few mm in size, all the way up to 5 ft (1.5 m), with exceptional resolution and accuracy and virtually no part shrink or warping. ● Selective Laser Sintering (SLS) Capable of producing highly durable and complex geometries for real-world testing while other additive manufacturing methods may become brittle over time. Ideal for snap fits a... -

Top Suppliers Brazing Aluminum Sheet Metal - Sheet metal operations from prototype to high volume production – Colead

Description Sheet metal can be cut, bent, and stretched into nearly any shape. The size of sheet metal parts can range from a small washer or bracket to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture. Quotes are generated with STEP, IGES or most native CAD files. Material thickness can range from 0.001″ – 0.250″. Advantages ... -

Best Price on Elastomer Injection Molding - Most common way to produce large volume production – Colead

Description Currently plastic injection molding is still the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use. Advantages There are many advantages of injection molding: ● Wide plastic resins to choose from for any application. ● Standard lead time 2-4 weeks for T1 samples. ● Most cost-effective way to make large volumes of parts fast. ● A single tool can last for up to millions of cycles. ● Excellent surface quality and dim... -

Rapid Delivery for Rapid Prototyping Design - Build prototyping parts without limitation of geometry by 3D Printing – Colead

Description ● Stereolithography (SLA) Highest accuracy and smoothest surface finish of all 3D printed parts. Print highly detailed parts ranging from just a few mm in size, all the way up to 5 ft (1.5 m), with exceptional resolution and accuracy and virtually no part shrink or warping. ● Selective Laser Sintering (SLS) Capable of producing highly durable and complex geometries for real-world testing while other additive manufacturing methods may become brittle over time. Ideal for snap fits a... -

Reasonable price for Thermoplastic Injection - Most common way to produce large volume production – Colead

Description Currently plastic injection molding is still the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use. Advantages There are many advantages of injection molding: ● Wide plastic resins to choose from for any application. ● Standard lead time 2-4 weeks for T1 samples. ● Most cost-effective way to make large volumes of parts fast. ● A single tool can last for up to millions of cycles. ● Excellent surface quality and dim...