Low volume plastic production for pre-run by Urethane Casting

Description

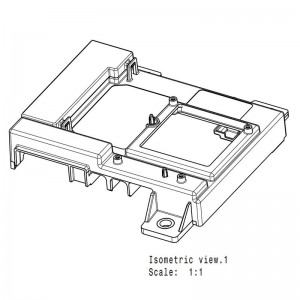

From product development models and prototypes to low-volume production runs, this rapid prototyping process allows us to produce parts that accurately mimic the color, texture, feel and physical properties of injection molded parts.

Advantages

Among the many advantages of urethane casting are the following:

● Accurately mimic production colors and textures.

● Large material selection – rigid, flexible, durable, clear and high-temp offers similar physical properties to injection molded parts.

● Used for pre-production runs.

● Self-colored parts.

● Parts made for marketing samples and test prototypes.

● Low-volume manufacturing.

● Cast Urethane parts can be complete and delivered in days after completing SRM tooling (Silicone Rubber Molds). Short runs of several hundred pieces can be delivered within weeks in most instances.

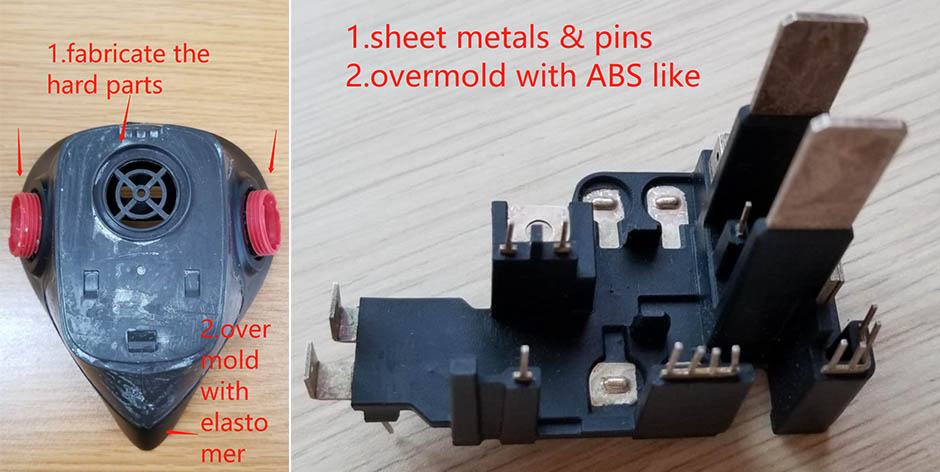

● One of the greatest benefits of the Cast Urethane process is the ability to over-mold existing parts or hardware with a second material.

Materials

ABS Like

Flame Resistant ABS Like

PA Like

PP Like

PC Like

PMMA Like

ELASTOMER (30A-90A)

Etc

Finish

Color Match

Texture

Application

Vehicle \ Electronics \Medical devices\Cosmetics etc.

Urethane casting enables us to quickly recreate tens of parts in production like materials, and allowing us to create multiple reproductions of a part for market or in-house testing. There are a lot of things we can do when designing your part to ensure it is a good fit for urethane casting. Pls contact us freely if you need any help in rapid prototyping work or low volume production.