OEM Manufacturer Application Of Rapid Tooling - Low volume production by rapid tooling technology – Colead

OEM Manufacturer Application Of Rapid Tooling - Low volume production by rapid tooling technology – Colead Detail:

Description

Rapid tooling is a technique to simplify the mold structures for low cost & short lead-time. Base on low-volume request, it’s generally used in the field of rapid injection molding. Colead manufactures its own rapid tooling in 7075 Aluminum (molds can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are fitted into a Master Unit Die (MUD based system) with standard tooling components, in order to produce Injection Molding parts.

Rapid aluminum tooling is very suitable or low-volume production prototype runs, it provides a cost effective solution with shorter lead-time than traditional production tooling. For Rapid Tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional tooling.

Typically, we are able to go from initial DFM design through to tooling manufacture, mold flow analysis, and initial samples in approximately 5 to 28 calendar days.

Advantages

Our professional knowledge and experiences in rapid manufacturing really can be helpful to save a lot of the time & cost for your prototyping works.

Among the many advantages of rapid tooling are the following:

● Prototypes can be produced in production material in shorter timeframes.

● Allows for full fit and function testing.

● Discovery of any design flaws early on, low cost tooling allows for easy geometry modification and refinement of design.

● Prototype tooling in 5 to 28 calendar days.

● Rapid aluminum tooling for volumes up to 5000+ pcs.

● P20 prototype tooling for volumes up to 50,000+ pcs.

● NAK80 or S136 prototype tooling for volumes up to 100,000+ shots.

At Colead, we bridge prototype and production by rapid tooling technology, we make low volume production to help your market testing.

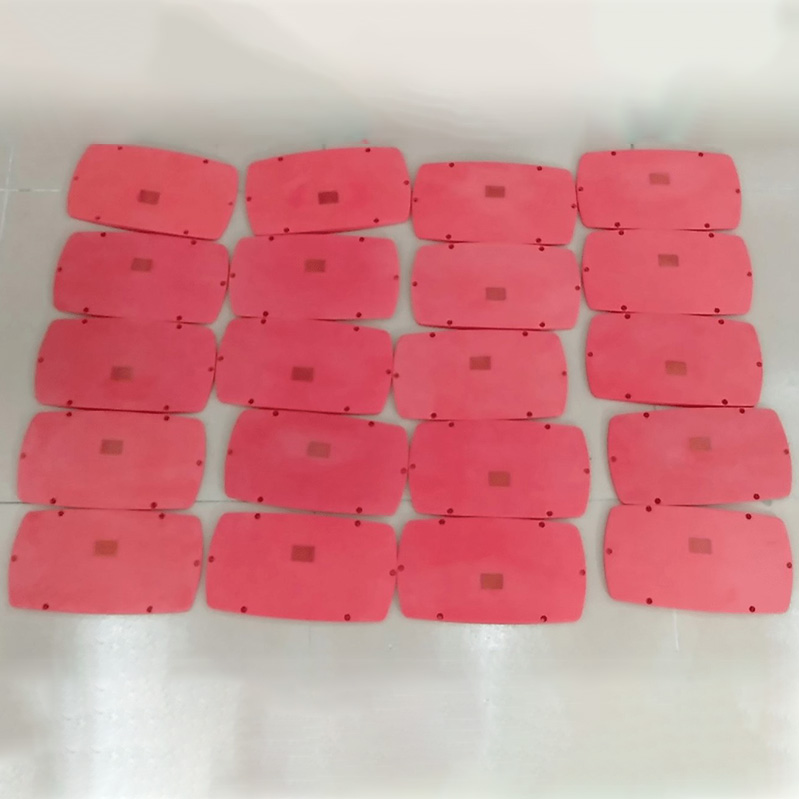

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for OEM Manufacturer Application Of Rapid Tooling - Low volume production by rapid tooling technology – Colead , The product will supply to all over the world, such as: Greenland, Jamaica, Roman, We offer the great variety of products in this field. Besides, customized orders are also available. What's more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.