Personlized Products Liquid Injection Molding - Most common way to produce large volume production – Colead

Personlized Products Liquid Injection Molding - Most common way to produce large volume production – Colead Detail:

Description

Currently plastic injection molding is still the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use.

Advantages

There are many advantages of injection molding:

● Wide plastic resins to choose from for any application.

● Standard lead time 2-4 weeks for T1 samples.

● Most cost-effective way to make large volumes of parts fast.

● A single tool can last for up to millions of cycles.

● Excellent surface quality and dimensional characteristics can be achieved.

● Variety of polishing and texturing capabilities.

● Different plastics can be overmolded for even more design options.

● Injection molding is stable and reliable for predictable result.

● Free Design for Manufacturing Analysis (DFM) with each quote.

Application

Almost for every kind of commercial and industrial use.

In Colead we are producing high-quality plastic injection molded parts and mold tooling. We supply plastic injection manufacturing for many world first -class companies. We are offering all machining and finishing services to make tooling from a variety of materials, and produce 100 to 200k+ finished parts in all major plastics. Our advanced material verification, inspection and testing will ensure your parts meet and exceed your expectations.

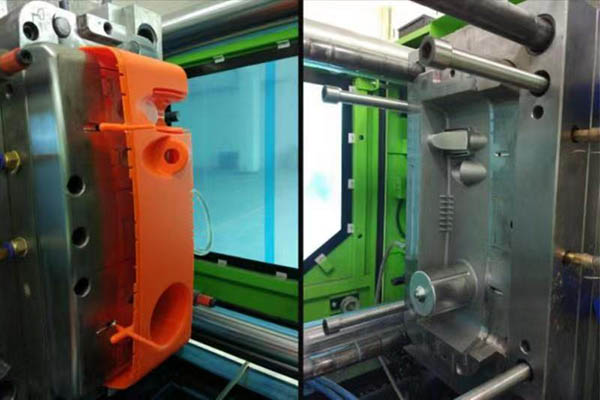

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Personlized Products Liquid Injection Molding - Most common way to produce large volume production – Colead , The product will supply to all over the world, such as: Bahrain, Swaziland, Bahrain, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!